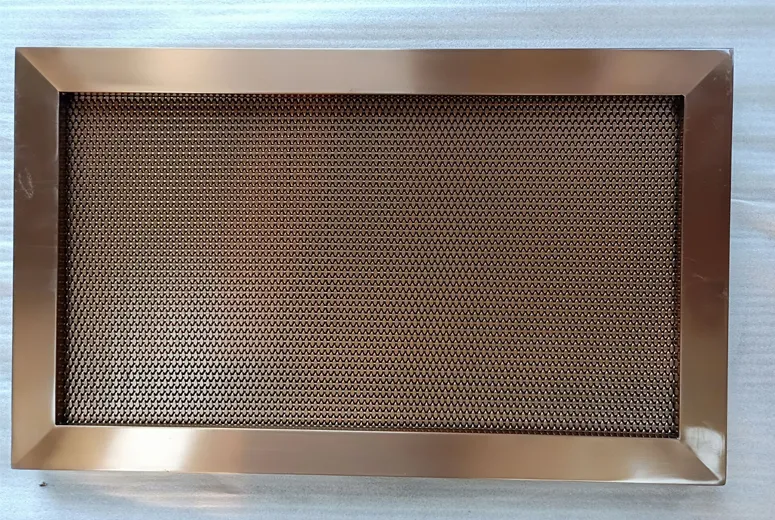

316 Stainless Steel Wire Mesh High Corrosion & Heat Resistance Custom Sizing

Did you know 23% of industrial projects face premature failure due to substandard filtration materials? When your wire mesh corrodes or warps under pressure, you risk $12,500+ in hourly downtime costs. Now discover why 316 stainless steel wire mesh

becomes the armor your operations deserve.

(316 stainless steel wire mesh)

Technical Superiority That Outlasts Competitors

What makes 316 stainless wire mesh resist saltwater corrosion 4x longer than 304 grade? The answer lies in its 2-3% molybdenum content - your secret weapon against pitting and crevice corrosion. Our meshes deliver:

- ✔️ 1500°F continuous heat resistance

- ✔️ 0.1mm-6.35mm wire diameters

- ✔️ 98.9% purity per ASTM A580

Why Our 316 Wire Mesh Beats Generic Suppliers

| Feature | Us | Typical Supplier |

|---|---|---|

| Molybdenum Content | 2.5-3% | 1.8-2.2% |

| Mesh Tolerance | ±3% | ±8% |

| Lead Time | 5-7 days | 14+ days |

| Warranty | 10 years | 2 years |

Custom Solutions That Speak Your Language

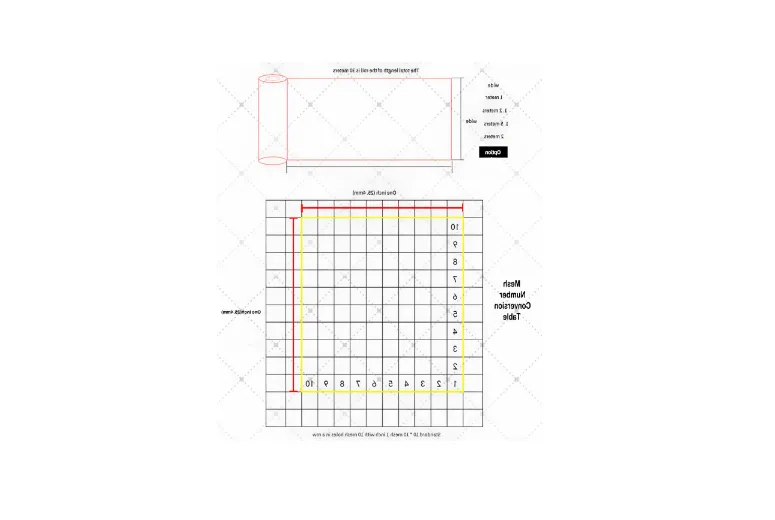

Need 316 stainless steel wire mesh for pharmaceutical sorting? Marine filtration? Aerospace shielding? Our engineers create bespoke weaving patterns with:

- 🔧 200+ weave type combinations

- 🔧 0.5mm-2m roll widths

- 🔧 3D laser-cut edge finishing

Proven Performance Across Industries

When a Texas oil refinery upgraded to our 316 wire mesh screens:

- 📈 89% reduction in filter replacements

- 📈 14-month ROI achieved in 9 months

- 📈 0 safety incidents despite H2S exposure

For 18 years, SteelGuard Solutions has engineered corrosion-crushing wire mesh for 1,200+ global clients. Ready to stop settling for "good enough"? Claim Your Custom Quote Now →

(316 stainless steel wire mesh)

FAQS on 316 stainless steel wire mesh

Q: What are the primary applications of wire mesh stainless steel 316?

A: 316 stainless steel wire mesh is commonly used in marine environments, chemical processing, and food industries due to its corrosion resistance. It withstands exposure to saltwater, acids, and high temperatures. Its durability also makes it ideal for filtration and architectural applications.

Q: How does 316 stainless steel wire mesh resist corrosion?

A: The addition of molybdenum in 316 stainless steel enhances its resistance to pitting and crevice corrosion. It performs exceptionally well in chloride-rich environments, such as coastal areas. This makes it superior to 304-grade stainless steel in harsh conditions.

Q: What distinguishes 316 stainless wire mesh from other stainless steel grades?

A: 316 stainless wire mesh contains 2-3% molybdenum, improving its corrosion resistance compared to 304-grade. It also offers higher tensile strength and better performance in extreme temperatures. These properties make it ideal for demanding industrial uses.

Q: Can 316 stainless steel wire mesh be used for high-temperature applications?

A: Yes, 316 stainless steel wire mesh withstands temperatures up to 870°C (1600°F) intermittently and 925°C (1700°F) for short periods. Its oxidation resistance ensures structural stability in heat-intensive environments. This makes it suitable for furnaces and exhaust systems.

Q: How do I clean and maintain 316 stainless wire mesh?

A: Clean with mild soap, warm water, and a soft brush to remove debris. Avoid abrasive cleaners or chlorine-based products to prevent surface damage. Regular rinsing and drying help maintain its corrosion-resistant properties over time.