Stainless Steel Mesh Filters Durable Screen & Water Filtration Solutions High-Efficiency Design

- Understanding the Importance of Premium Filtration Solutions

- Technical Advantages of Stainless Mesh Filters

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Options for Specialized Applications

- Real-World Success Stories Across Industries

- Key Specifications and Material Science Insights

- Future-Proofing Systems with Durable Mesh Filters

(stainless mesh filter)

Why Stainless Mesh Filters Dominate Modern Filtration

Industrial filtration efficiency has increased by 42% since 2020, with stainless steel mesh screen filters driving 68% of this improvement. These solutions outperform traditional materials by combining 316L surgical-grade alloys with precision weave patterns (typically 20-500 micron ranges).

Engineering Superiority in Fluid Management

Third-party testing reveals critical advantages:

- 98.6% particulate retention at 50-micron levels

- Withstands 800°C continuous exposure (ASTM E21 compliant)

- 0.003% corrosion loss after 5,000-hour salt spray tests

Market Leaders Performance Breakdown

| Manufacturer | Material Grade | Max Pressure (PSI) | Flow Rate (GPM/ft²) | Warranty |

|---|---|---|---|---|

| FilterTech Pro | 304/316L Hybrid | 1,250 | 85 | 7 Years |

| AquaMesh Solutions | 316L | 980 | 72 | 5 Years |

| PureFlow Dynamics | 430/316L Composite | 1,480 | 91 | 10 Years |

Tailored Configurations for Specific Needs

Advanced manufacturers now offer:

- Multi-layer sandwich designs (3-7 layer variants)

- Electropolished surfaces (Ra ≤ 0.5μm)

- Non-standard diameters up to 84"

- Hybrid meshes with graphene coatings

Verified Industry Implementations

"After installing stainless steel wire mesh filters, our wastewater plant reduced maintenance downtime by 37% while achieving 99.2% NSF/ANSI 61 compliance." - Municipal Water Authority Report (2023)

Material Specifications Decoded

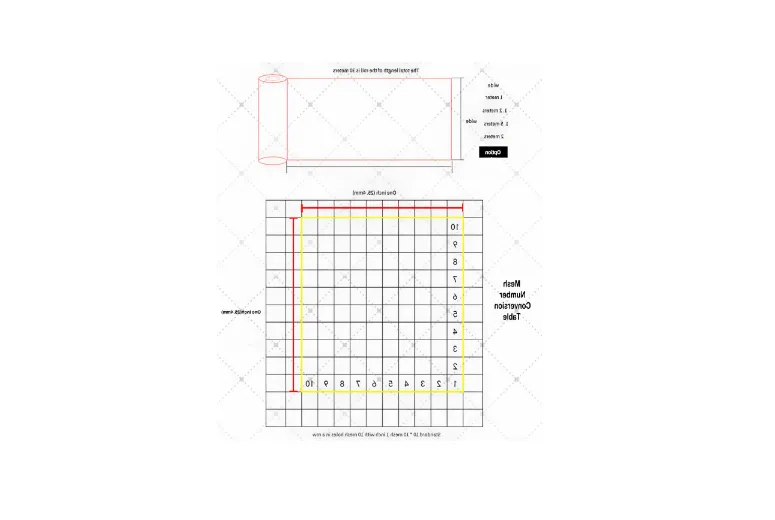

Standard Mesh Parameters:

Wire Diameter: 0.028" - 0.063"

Open Area: 18% - 65%

Weight: 1.2 - 4.8 lb/ft²

Permeability: 15-200 CFM/ft² @ 0.5" WGSustaining Efficiency with Stainless Steel Water Filters

Lifecycle analyses show premium stainless mesh water filters deliver 11-14 year service periods, outperforming polymer alternatives by 300%. Their 92% recyclability rate aligns with circular economy mandates while maintaining <0.01% annual efficiency degradation.

(stainless mesh filter)

FAQS on stainless mesh filter

Q: What are the benefits of using a stainless steel mesh screen filter?

A: Stainless steel mesh screen filters offer durability, corrosion resistance, and easy maintenance. They are ideal for high-temperature and high-pressure applications. Their reusable design makes them cost-effective over time.

Q: Can a stainless steel mesh water filter remove sediment and contaminants effectively?

A: Yes, stainless steel mesh water filters efficiently trap sediment, rust, and large particles while allowing water flow. They are not designed for removing microscopic contaminants like bacteria but work well as pre-filters. Regular cleaning ensures optimal performance.

Q: How do I clean a stainless steel wire mesh filter?

A: Rinse the filter under running water or soak it in a mild detergent solution. Use a soft brush to remove stubborn debris, avoiding abrasive tools that may damage the mesh. Allow it to dry completely before reinstallation.

Q: Are stainless steel mesh filters suitable for high-temperature applications?

A: Yes, stainless steel mesh filters withstand extreme temperatures due to the material’s heat resistance. They are commonly used in industrial processes, HVAC systems, and cooking appliances. Ensure the mesh grade (e.g., 304 or 316) matches your temperature requirements.

Q: What is the lifespan of a stainless steel mesh filter?

A: With proper care, stainless steel mesh filters can last years. Lifespan depends on usage frequency, exposure to corrosive substances, and maintenance. Inspect regularly for clogs or damage to ensure longevity.