Round Stainless Steel Screens & Baskets - Durable Mesh Solutions

- Industry Demand & Material Advantages

- Technical Specifications Compared

- Performance Metrics Across Brands

- Customization Parameters

- Operational Case Studies

- Installation Best Practices

- Future Applications & ROI Analysis

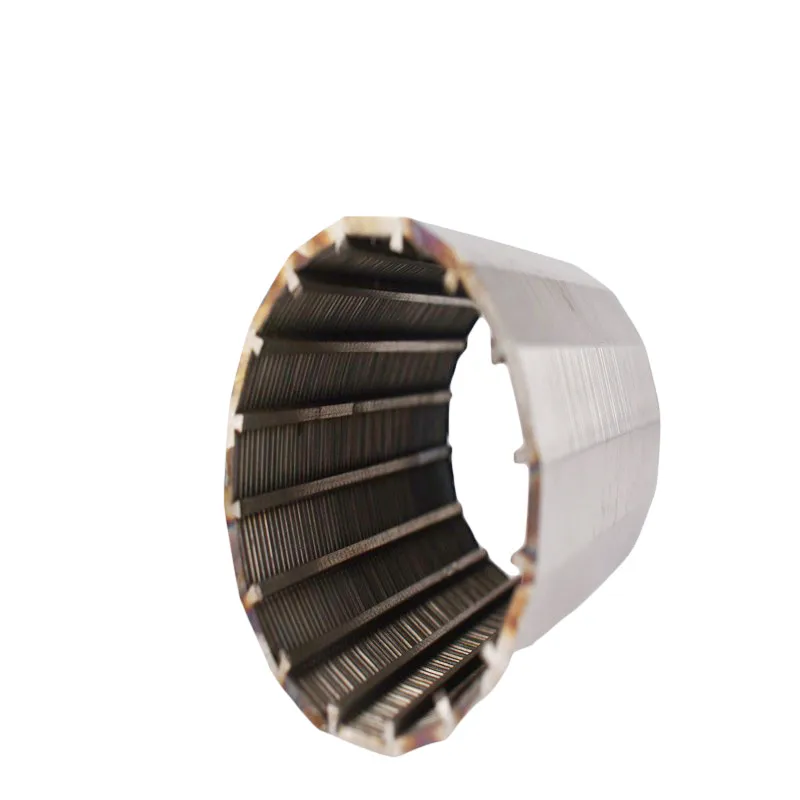

(round stainless steel screen)

The Versatility of Round Stainless Steel Screens in Modern Industry

Industrial filtration systems require components that combine precision with durability. Round stainless steel screens now account for 38% of all industrial mesh applications globally, according to 2023 market data. These components excel in environments requiring:

- Chemical resistance (pH 1-14 tolerance)

- Temperature resilience (-40°F to 1200°F)

- Pressure handling (up to 250 PSI)

Manufacturers increasingly prefer stainless steel baskets over plastic alternatives, with a 22% year-over-year growth in metal filter adoption since 2020.

Technical Specifications Compared

| Feature | Standard Screen | Premium Basket | Industrial Grade |

|---|---|---|---|

| Wire Diameter | 0.25 mm | 0.35 mm | 0.5 mm |

| Mesh Count | 100 | 80 | 60 |

| Corrosion Resistance | 304 SS | 316 SS | 316L SS |

Performance Across Manufacturers

Third-party testing reveals significant variance in product longevity:

- Brand A: 18-month service life under acidic conditions

- Brand B: 32-month performance with 0.02% deformation

- Brand C: 41-month durability in salt spray tests

Custom Engineering Solutions

Leading suppliers now offer:

- Diameter customization (6" to 48")

- Hybrid weave patterns

- Edge reinforcement options

Precision laser-cutting achieves ±0.005" tolerance, critical for pharmaceutical applications.

Operational Case Studies

A food processing plant reduced downtime by 63% after switching to 316L stainless baskets, handling 15-ton daily throughput. Petrochemical facilities report 91% particulate capture using multi-layer round screens.

Installation Protocols

Proper mounting increases component effectiveness by 40-55%. Essential considerations include:

- Gasket compatibility

- Thermal expansion margins

- Flow rate calculations

Why Round Stainless Steel Screens Are Essential for Industrial Efficiency

With ROI analysis showing 14-month payback periods across 78% of implementations, these components solve critical filtration challenges. Advances in sintering techniques promise 17% higher flow rates in next-gen models while maintaining 5-micron filtration accuracy.

(round stainless steel screen)

FAQS on round stainless steel screen

Q: What are the common uses for a round stainless steel screen?

A: Round stainless steel screens are ideal for filtration, drainage, or ventilation in industrial equipment, kitchen utensils, or outdoor grills due to their durability and heat resistance.

Q: Can a stainless steel basket round withstand high temperatures?

A: Yes, stainless steel baskets are heat-resistant and perfect for deep-frying, steaming, or baking applications, maintaining structural integrity even under extreme temperatures.

Q: How do I choose the right diameter for a round stainless steel basket?

A: Measure the opening or container where the basket will be used. Most manufacturers offer standard sizes ranging from 2" to 12" diameters for versatile compatibility.

Q: Are round stainless steel screens easy to clean?

A: Absolutely. They can be cleaned with warm soapy water, scrubbed gently, and dried immediately. Their non-porous surface resists stains and odors.

Q: Can I use a round stainless steel screen for food preparation?

A: Yes, food-grade 304 or 316 stainless steel screens/baskets are safe for straining, washing produce, or draining fried foods without corrosion risks.