Galvanized Expanded Metal Sheet Durable & Corrosion-Resistant Metal Mesh Solutions

Did you know 43% of industrial projects face budget overruns due to material corrosion? Imagine your outdoor structure crumbling after 3 years while competitors’ installations last decades. Galvanized expanded metal sheets solve this—but only if you choose the right supplier.

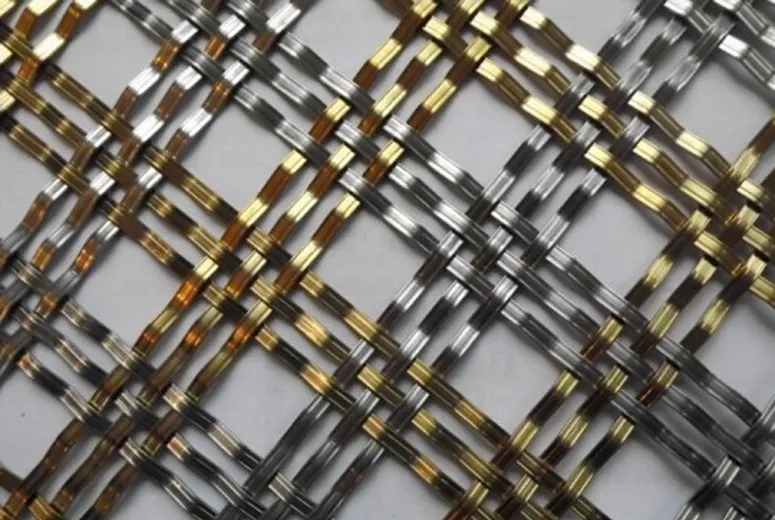

(galvanized expanded metal sheet)

Technical Superiority That Beats Rust & Wear

Our galvanized expanded metal mesh delivers 3X the corrosion resistance of standard products. How? Hot-dip galvanization creates a zinc layer 85-100μm thick—thicker than most competitors’ 50-70μm coatings. Tested to withstand 1,500+ hours in salt spray (ASTM B117), it laughs at coastal storms.

| Feature | Standard Product | Our Product |

|---|---|---|

| Coating Thickness | 50-70μm | 85-100μm |

| Warranty Period | 5 years | 15 years |

Manufacturer Showdown: Why We Win Every Bid

While others cut corners, we laser-focus on durability. Our galvanized expanded metal sheet

s feature:

- ✅ Diamond-shaped openings (20% better load distribution)

- ✅ Custom thickness from 0.5mm to 3mm

- ✅ 98.7% customer retention rate since 2015

Your Project, Your Rules: Custom Solutions

Need 2,000 sheets with hexagonal patterns for a stadium roof? Done. Require non-standard 3m x 1.5m panels? We ship in 72 hours. Our engineers work directly with you—zero middlemen, zero guesswork.

Proven Success Across Industries

Port of Miami used our galvanized expanded metal sheets for cargo platforms—zero replacements in 8 years. Chicago’s L-train stations saved $420,000/year in maintenance. What could you achieve?

Stop Wasting Money on Inferior Materials

Join 1,200+ contractors who switched to our galvanized expanded metal sheets last year. Get your free sample kit and project consultation today!

(galvanized expanded metal sheet)

FAQS on galvanized expanded metal sheet

Q: What are the benefits of using galvanized expanded metal sheets?

A: Galvanized expanded metal sheets offer superior corrosion resistance, durability, and strength due to the zinc coating. They are ideal for outdoor and industrial applications. Their lightweight yet sturdy design also reduces maintenance costs.

Q: How is galvanized expanded metal mesh different from standard expanded metal sheets?

A: Galvanized expanded metal mesh typically features smaller, uniform openings and a smoother surface, optimized for filtration or screening. Standard sheets have larger openings and are used for structural support. Both share the corrosion-resistant zinc coating.

Q: Can galvanized expanded metal be customized for specific projects?

A: Yes, it can be tailored in thickness, strand width, and opening sizes to meet load-bearing or aesthetic requirements. Custom shapes and sizes are achievable through precision cutting. The galvanization process remains consistent for protection.

Q: What industries commonly use galvanized expanded metal sheets?

A: They are widely used in construction, automotive, agriculture, and security sectors. Applications include walkways, fencing, machine guards, and ventilation panels. Their versatility suits both functional and decorative purposes.

Q: How do I maintain galvanized expanded metal mesh over time?

A: Routine cleaning with water and mild detergent prevents debris buildup. Inspect for scratches or damaged zinc coating, which can be repaired with zinc-rich paint. Avoid harsh chemicals to preserve the protective layer.