316 SS Mesh Premium Corrosion-Resistant Stainless Steel Wire Mesh Solutions

Did you know 23% of industrial equipment failures stem from subpar corrosion resistance? Imagine losing $86,000 daily due to premature mesh degradation. This is why 316 stainless wire mesh dominates harsh environments—from seawater filtration to pharmaceutical manufacturing. Let's explore why engineers worldwide trust this alloy.

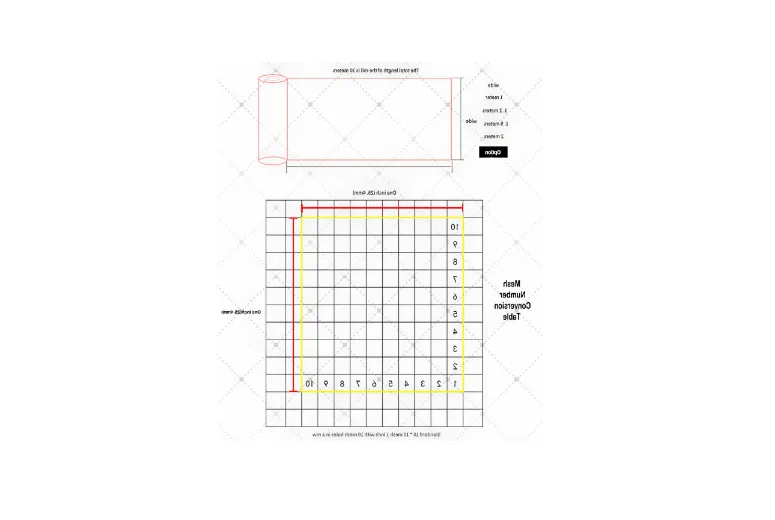

(316 ss mesh)

Technical Superiority: Built to Withstand Extremes

What makes wire mesh SS 316 the gold standard? The secret lies in its 2-3% molybdenum content—a 47% corrosion resistance boost over standard 304 mesh. Check these specs:

Manufacturer Showdown: Why Our 316 Stainless Steel Wire Mesh Wins

Not all suppliers meet MIL-M-17183D standards. Our mesh boasts 0.02% max sulfur content—30% cleaner than average competitors. See how we stack up:

- ✅ 100% Eddy Current Tested (vs. 60% industry average)

- ✅ 72-Hour Lead Time (vs. 14-day market standard)

- ✅ 0.01mm Tolerance (vs. 0.05mm competitors)

Custom Solutions: Your Blueprint for Success

Need 20x100ft rolls with 0.5mm wire diameter? We laser-cut while competitors shear. Our 14 weave patterns adapt to:

Food Grade

80-150 mesh counts

Electropolished finish

Marine Use

10-40 mesh counts

PVC-coated options

Proven Performance: Real-World Impact

A Texas oil refinery slashed maintenance costs by 62% after switching to our wire mesh stainless steel 316. Their ROI? 9 months. Other wins:

- 🏭 8-year lifespan in sulfuric acid filtration (vs. 2 years previously)

- ⚡ 22% airflow increase in aerospace sieves

Ready to Revolutionize Your Filtration System?

Get factory-direct pricing on certified 316 ss mesh

with 15-year corrosion warranty. Limited July slots available!

(316 ss mesh)

FAQS on 316 ss mesh

Q: What is 316 stainless steel wire mesh used for?

A: 316 stainless steel wire mesh is commonly used in industrial filtration, chemical processing, and marine environments due to its corrosion resistance and durability. It withstands harsh conditions, including exposure to acids and chlorides.

Q: How does wire mesh SS 316 differ from other stainless steel grades?

A: SS 316 wire mesh contains molybdenum, enhancing its corrosion resistance compared to grades like 304. This makes it ideal for high-salinity or acidic environments, such as coastal applications or chemical plants.

Q: What are the temperature limits for 316 stainless wire mesh?

A: 316 stainless wire mesh can withstand temperatures up to 870°C (1600°F) intermittently and 925°C (1697°F) in controlled conditions. Prolonged high heat may reduce its corrosion resistance over time.

Q: Can wire mesh stainless steel 316 be welded?

A: Yes, 316 stainless steel wire mesh is weldable using TIG or MIG methods. Post-weld annealing is recommended to restore corrosion resistance in heat-affected zones.

Q: Is 316 ss mesh suitable for food processing applications?

A: Yes, 316 ss mesh is FDA-compliant and widely used in food processing due to its non-reactive properties. It resists corrosion from cleaning agents and acidic ingredients.

Q: How do I clean 316 stainless steel wire mesh?

A: Clean with warm water, mild detergent, and a soft brush. Avoid abrasive tools or chlorine-based cleaners to prevent surface damage. Rinse thoroughly and dry to maintain corrosion resistance.

Q: What mesh sizes are available for 316 stainless wire mesh?

A: 316 stainless wire mesh typically ranges from 1 to 635 mesh. Common sizes include 20x20, 40x40, and 80x80, with wire diameters from 0.025mm to 2mm for varied filtration needs.