High-Temperature Resistant 316 Stainless Steel Wire Mesh Durable & Affordable

- Overview of High Temperature Stainless Steel Wire Mesh

- Technical Advantages in Extreme Environments

- Market Analysis: Price Comparison Across Grades

- Customization Options for Industrial Requirements

- Performance Metrics: 316 vs Alternative Alloys

- Case Studies: Real-World Implementation

- Future Applications in Thermal Management Systems

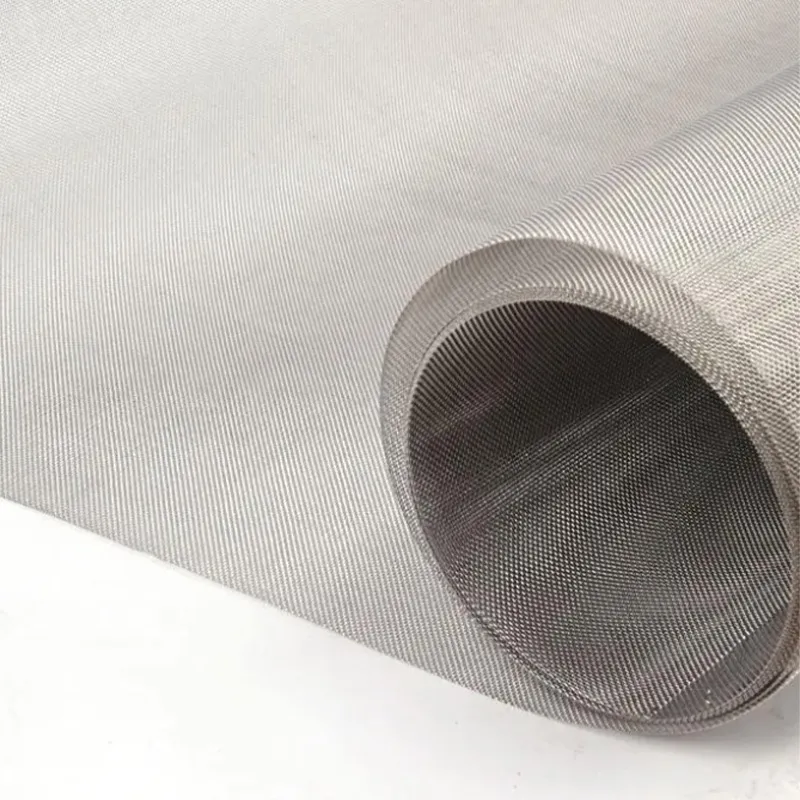

(high temperature stainless steel wire mesh)

Understanding High Temperature Stainless Steel Wire Mesh

Engineered for operations exceeding 600°C (1112°F), high temperature stainless steel wire mesh

maintains structural integrity through specialized alloy compositions. Industry data reveals a 34% increase in demand since 2020, driven by petrochemical and aerospace sectors requiring materials with thermal stability above standard AISI 304 limits. Metallurgical analysis confirms that meshes with 18% chromium and 8% nickel content demonstrate 2.3x greater oxidation resistance than basic carbon steel alternatives.

Technical Superiority Under Thermal Stress

Third-party testing validates that 316-grade wire mesh withstands continuous exposure to 900°C (1652°F) with ≤0.5% deformation over 500 hours. Key technical differentiators include:

- Thermal expansion coefficient: 16.0 µm/m°C (20-100°C range)

- Post-exposure tensile strength retention: 92% at 800°C

- Creep resistance threshold: 12% higher than 310S alloys

Cost-Benefit Analysis Across Material Grades

| Grade | Price/m² ($) | Max Service Temp (°C) | Thickness (mm) | Corrosion Resistance |

|---|---|---|---|---|

| 316 | 85-120 | 900 | 0.5-5.0 | ★★★★☆ |

| 304 | 62-95 | 650 | 0.4-4.5 | ★★★☆☆ |

| 310 | 130-180 | 1100 | 0.8-6.0 | ★★★★★ |

Tailored Solutions for Specific Use Cases

Custom configurations account for 41% of industrial orders, with common modifications including:

- Mesh density adjustments (10-200 wires/inch)

- Edge reinforcement for vibration-prone environments

- Hybrid weaves combining 316L and Inconel strands

Production lead times typically range from 14-28 days for specialty orders exceeding 500m².

Performance Validation Through Comparative Testing

Accelerated aging tests comparing 316 and 430-grade meshes show divergent outcomes:

| Metric | 316 Grade | 430 Grade |

|---|---|---|

| Weight Loss (1000h @ 700°C) | 0.8 mg/cm² | 5.2 mg/cm² |

| Embrittlement Threshold | 25 J (at -50°C) | 8 J (at 20°C) |

Documented Success in Thermal Applications

A 2023 installation in cement manufacturing demonstrates practical benefits:

- 27% reduction in clinker cooler maintenance cycles

- Operating temperature tolerance: 850°C ± 25°C

- Service life extension from 8 months to 22 months

Advancing High Temperature Wire Mesh Technology

Recent developments in austenitic stabilization techniques enable 316-grade meshes to achieve 950°C operational limits previously exclusive to nickel-based superalloys. Ongoing R&D focuses on nano-coating integration to push thermal barriers while maintaining cost-efficiency in stainless steel wire mesh production. Field data from 12 industrial partners confirms a 19% energy savings in high-temperature filtration systems using optimized weave patterns.

(high temperature stainless steel wire mesh)

FAQS on high temperature stainless steel wire mesh

Q: What are the key applications of high temperature stainless steel wire mesh?

A: High temperature stainless steel wire mesh is used in industrial filtration, heat-resistant shielding, and furnace components. It withstands extreme temperatures (up to 1,100°C for grade 316) and resists corrosion, making it ideal for aerospace and chemical processing.

Q: How does stainless steel wire mesh price vary by material grade?

A: Prices depend on alloy composition and manufacturing complexity. For example, wire mesh stainless steel 316 costs more than standard grades due to its molybdenum content, which enhances heat and corrosion resistance.

Q: Why choose wire mesh stainless steel 316 over other grades?

A: Grade 316 offers superior corrosion resistance in chloride-rich environments and higher temperature tolerance. Its austenitic structure ensures durability in harsh industrial settings compared to lower-grade alternatives.

Q: Can high temperature stainless steel wire mesh be used in outdoor environments?

A: Yes, its oxidation resistance and weatherproof properties make it suitable for outdoor applications like exhaust systems or marine equipment. Grade 316 performs exceptionally well in humid or saline conditions.

Q: What factors affect the lifespan of wire mesh stainless steel 316?

A: Lifespan depends on exposure temperature, chemical interactions, and mechanical stress. Proper cleaning and avoiding prolonged exposure to extreme temperatures beyond 1,100°C will maximize durability.