Chemical Composition of 304 Stainless Steel Mesh

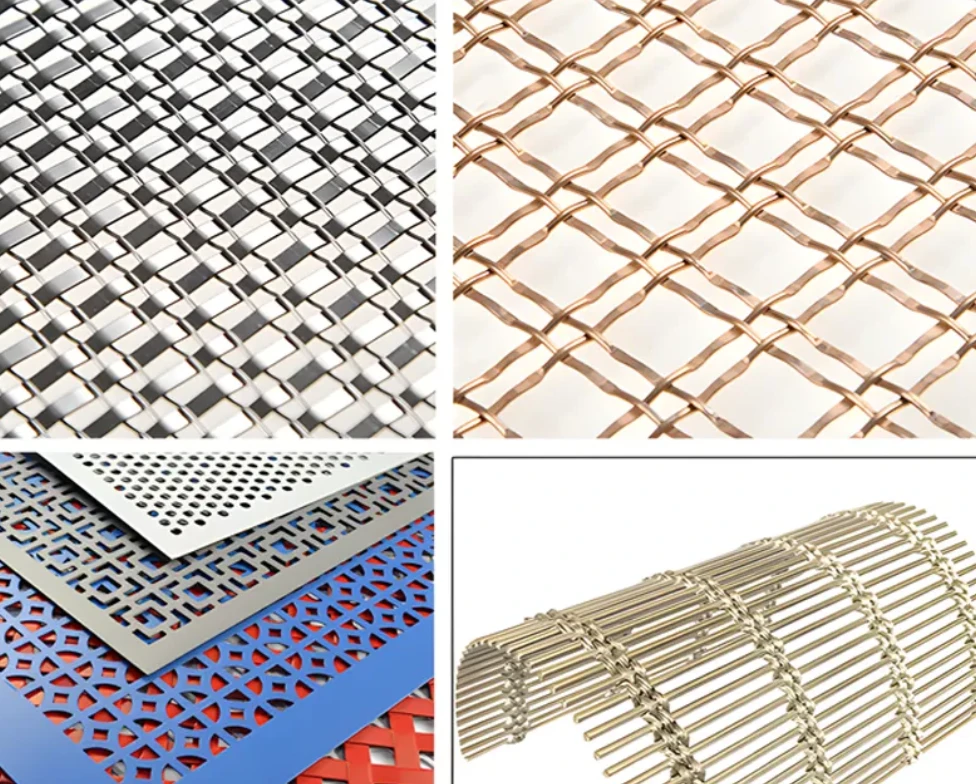

The chemical composition of 304 stainless steel mesh is fundamental to its exceptional properties, making it a staple in various industrial and commercial applications. Siatka druciana ze stali nierdzewnej, 304 stainless mesh, and 304 stainless steel mesh owe their durability, corrosion resistance, and versatility to a precise blend of metals. Stainless steel wire mesh is a highly corrosion-resistant material made by weaving or welding stainless steel wires, which is widely used in various industries. Its unique physical and chemical properties make it an ideal choice, not only to resist the influence of various environmental factors, but also to maintain stable performance. Stainless steel wire mesh is often used in liquid filtration, gas filtration and solid dehydration due to its excellent high temperature resistance and aging resistance. Hebei Qunhui Metal Products Co., Ltd. leverages this optimal composition to produce high-quality mesh products, ensuring they meet the rigorous demands of diverse applications.

Core Alloys in 304 Stainless Steel Mesh

- Chromium Content: 304 stainless steel mesh typically contains 18–20% chromium, the key element responsible for its corrosion resistance. Chromium forms a passive oxide layer on the surface, preventing rust and degradation when exposed to moisture or oxygen. Hebei Qunhui Metal Products Co., Ltd. ensures strict adherence to this chromium range, enhancing the longevity of their 304 stainless steel mesh in humid or outdoor environments.

- Nickel Addition: With 8–10.5% nickel, 304 stainless steel meshgains improved ductility and formability, allowing it to be woven into fine or intricate patterns without cracking. Nickel also enhances the alloy’s resistance to certain chemicals, making the mesh suitable for industrial filtration. Hebei Qunhui Metal Products Co., Ltd. uses high-purity nickel to maintain these properties in their 304 stainless steel mesh

Minor Elements in 304 Stainless Mesh

- Carbon Limits: 304 stainless meshcontains a maximum of 0.08% carbon, which strengthens the alloy without compromising its corrosion resistance. Lower carbon content reduces the risk of carbide precipitation during welding, ensuring the mesh remains durable even after fabrication. Hebei Qunhui Metal Products Co., Ltd. controls carbon levels precisely in their 304 stainless mesh, maintaining its structural integrity in welded applications.

- Manganese and Silicon: Manganese (up to 2%) and silicon (up to 1%) are added to 304 stainless meshto improve its strength and weldability. These elements enhance the alloy’s ability to withstand high temperatures, making the mesh suitable for heat-intensive processes like industrial drying. Hebei Qunhui Metal Products Co., Ltd. balances these elements to optimize both strength and workability in their mesh.

Impact of Composition on Stainless Steel Wire Mesh Properties

- Corrosion Resistance: The chromium-nickel blend in stainless steel wire meshensures resistance to rust, acids, and alkalis, making it ideal for water treatment, food processing, and chemical filtration. Hebei Qunhui Metal Products Co., Ltd.’s stainless steel wire mesh retains this resistance even after prolonged exposure to harsh substances, outperforming lower-grade alloys.

- Mechanical Strength: The chemical composition of stainless steel wire meshgives it high tensile strength, allowing it to withstand heavy loads and pressure. This makes the mesh suitable for applications like safety barriers or industrial sieving, where durability is critical. Hebei Qunhui Metal Products Co., Ltd. tests each batch of stainless steel wire mesh to ensure it meets strength standards.

|

Nazwa produktu |

Siatka metalowa |

|

Miejsce produkcji |

Chiny Hebei |

|

Typ |

Produkt dostosowany |

|

Tworzywo |

304,316,316LStainless steel wire, Customized |

|

Technologia przetwarzania |

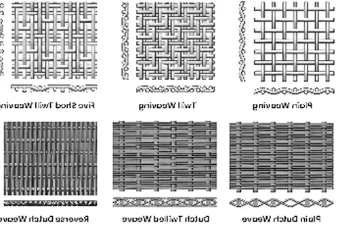

Splot ściegowy, splot płócienny, splot holenderski, splot skośny itp. |

|

Kolor |

Kolor metalu |

|

Rozmiar |

1mesh-3000mesh / Customized |

|

Scenariusz zastosowania |

Zastosowanie wielopolowe |

304 Stainless Steel Mesh Composition FAQS

Why is chromium critical in 304 stainless steel mesh?

Chromium is critical in 304 stainless steel mesh because it forms a protective oxide layer, preventing rust and corrosion. Hebei Qunhui Metal Products Co., Ltd. ensures their 304 stainless steel mesh has 18–20% chromium, making it suitable for wet or outdoor environments.

How does nickel affect 304 stainless mesh performance?

Nickel in 304 stainless mesh improves ductility, allowing it to be woven into fine patterns, and enhances chemical resistance. Hebei Qunhui Metal Products Co., Ltd.’s 304 stainless mesh uses 8–10.5% nickel to ensure flexibility and durability in diverse applications.

Can stainless steel wire mesh resist acidic environments?

Yes, stainless steel wire mesh (especially 304 grade) resists mild acids due to its chromium-nickel composition. Hebei Qunhui Metal Products Co., Ltd. notes it performs well in food processing or water treatment, though strong acids may require higher-grade alloys.

What is the maximum temperature 304 stainless steel mesh can withstand?

304 stainless steel mesh from Hebei Qunhui Metal Products Co., Ltd. can withstand temperatures up to 870°C (1600°F) continuously, making it suitable for high-heat applications like industrial ovens or drying systems.

How does composition affect the weldability of 304 stainless mesh?

The low carbon content (<0.08%) in 304 stainless mesh minimizes carbide precipitation during welding, ensuring strong, corrosion-resistant joints. Hebei Qunhui Metal Products Co., Ltd. leverages this composition to produce weldable mesh for custom fabrications.